Engineering

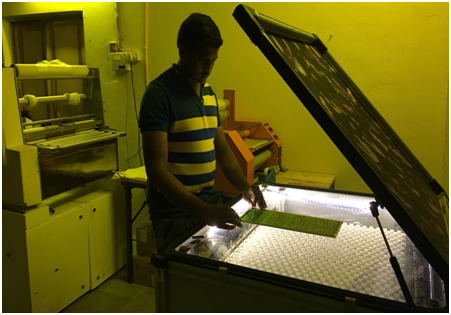

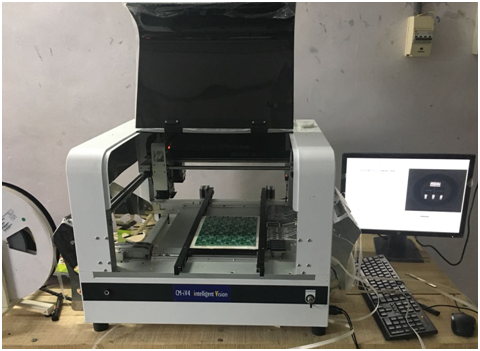

Engineering is one of the most critical processes in PCB manufacturing. The engineering works closely with the manufacturing engineer throughout the product life cycle.

Circuit electronics has dedicated and experienced engineers who are well equipped to handle convoluted and intricate design from customers (by provided customers) by also keeping in mind concept of production systemtechnical specification )/(the plant’s features/ capability ),

Concerned with ensuring that the products can made cost effectively and efficiently

Circuit electronics also involved works reverse engineering, PCB layout from schematic. We work to used design software on/in cadence, cam 350, u cam, Corel.